Hot Tap Line Stop

Applications - Solution - Services

Hot Tap - Line Stop

Applications - Solution - Services

Birawa provide Hottap and line stop services

Both of the Services are for our client existing production pipeline without the need to shutdown.

Hot tapping is also the first stop procedure, where a hole saw is used to create a gap in the pipe, so that the line connecting head can be inserted.

Hot Tapping is generally used to repair damaged or corroded areas, or add fittings for system modification.

Service Hottap

Application - Product - Services

Service Hot Tapping

Application - Product - Services

Service Hottap

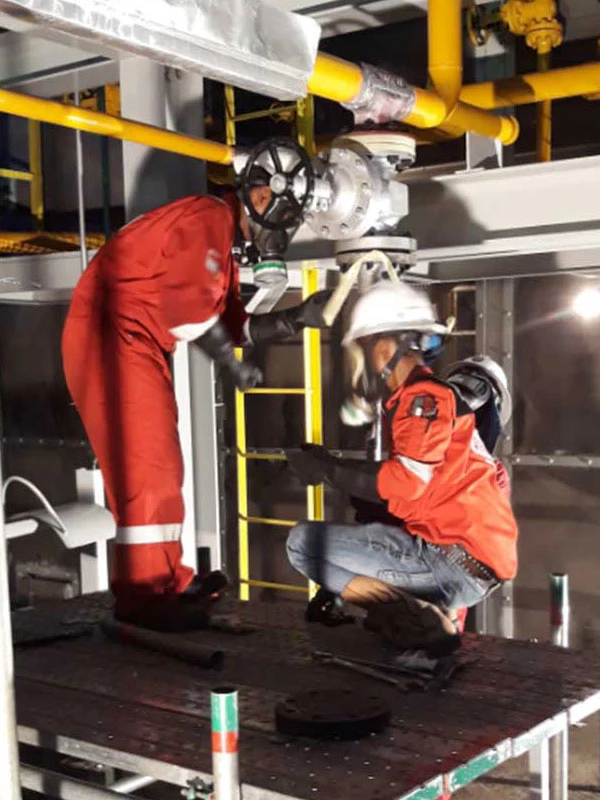

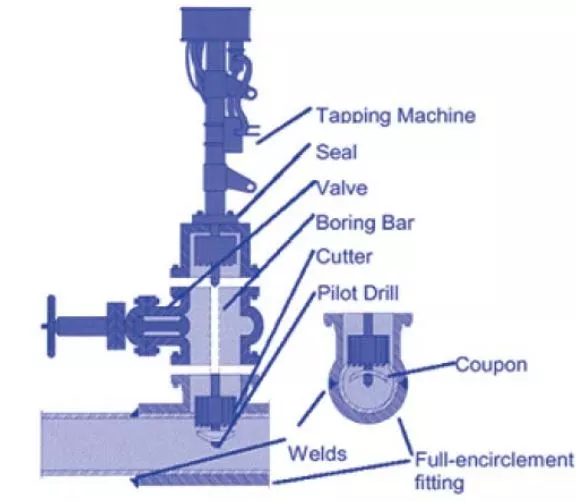

Hot Tapping refers to attaching connections and associated equipment to pipelines while they remain operational and/or under stress, minimizing impact and the potential costly need to shut down existing services.

This means that the pipe or tank can continue to operate while maintenance or modifications are being made to it. This process is also used to drain pressurized casing fluids, add test points or various sensors such as temperature and pressure. Hot Taps can range from inch holes designed for something as simple as quality control testing, to 48 inch taps for the installation of various ports, valves, t-sections or other pipes.

Delivering Safe and Effective Line Stopping

Line Stopping is a means of temporarily stopping flow in an operating pipe. Line Stopping can be used to isolate piping systems for repairs, alteration or relocations all without shutdown or loss of service to the end users.If used in conjunction with bypass lines, product flow can be continued around the isolated section of the one-way feed pipes under repair.

PT.Birawa Adhi Pratama is able to provide welding fittings to pressure pipes of various diameters and operating pressures to various welding specifications.

PT.Birawa also provides Hot Tap Services ranging from 1/2 inches to 42 inches.

Our Applications

- Preventing Shutdown

- Valve Installations

- New Construction Tie-Ins

- Thermowell Coupling Installation

- Installation of by-pass piping systems

Project Gallery

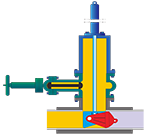

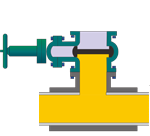

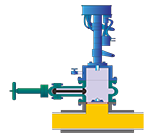

Procedure Hottap

General Hottap procedure application.

1. Install fitting & valve on existing pipeline

2. Install Hot Tap Machine

3. Perform Hot Tap through the open valve

4. Retract cutter assembly. A Special device retains the "Coupon" removed during Hot Tap Installation

5. Close Hot tapping valve

6. Removed Hot Tap machine

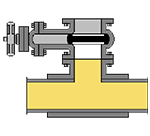

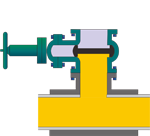

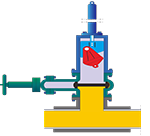

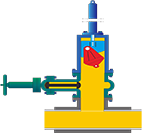

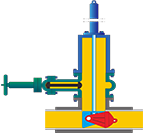

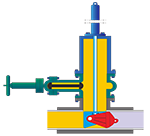

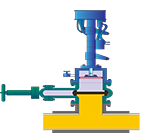

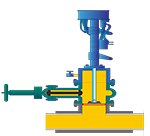

Procedure Line-Stop

General Line-Stop procedure application.

1. Remove Hot Tap Machine to allow connection for Line Stop Machine.

2. Line Stop equipment is installed on the temporary tap valve.

3. Valve open.

4. The Line Stop Head enters the pipe through the Hot connection.

5. The temporary seal is reached and the flow pipe is stopped.

6. The valve is temporarily closed and the Stop Line equipment will be removed.

7. Plug and Tapping Completion engine installed.

8. The temporary tapping valve is opened and the completion plug is put into position.

9. The temporary tapping valve is opened and the completion of the installed plug is locked into position.

10. The Line Stop equipment and tapping valve are temporarily removed from the line stop fitting.

11. Blind Flange is installed on the line stop fitting.